| Availability: | |

|---|---|

The features of X678 drop forged rivetless chain:

Material & Strength: The X678 drop forged rivetless chain is crafted from high-quality alloy steel, ensuring exceptional tensile strength (85,000 lbs) and durability for heavy-duty applications . Its fully heat-treated components resist wear and fatigue, making it ideal for harsh environments.

Rivetless Design: Featuring slotted sidebars and T-head pins, the X678 chain allows easy disassembly/assembly without tools, reducing maintenance time. This design also minimizes material buildup and enhances self-cleaning capabilities.

Precision Engineering: The chain incorporates precision-machined pins and bushings for smooth articulation and minimal friction, ensuring consistent performance in conveyor systems, overhead trolleys, and industrial machinery.

Versatile Applications: Suitable for automotive, steel manufacturing, and construction industries, the X678 chain excels in high-load scenarios like material lifts, paint lines, and swarf conveyors, thanks to its fire-resistant and oil-resistant properties.

Flexibility & Compatibility: With loose-link construction enabling lateral bend, the X678 chain offers flexibility for complex routing. It is directly interchangeable with other brands and supports various attachments and sprockets for customized solutions.

Brand Reputation: JINQIU CHAIN, as a prominent drop forged chains manufacturer, we offer a complete range of drop forged rivetless chain.

Quality & Performance: Drop forged rivetless chains are typically used asoverhead conveyors on automotive assembly lines, paint lines, appliance assembly lines, sugar mills and in the meat packaging industry.

Price & Value: We offer customization services to meet the specific needs of our clients. This includes OEM and ODM support, allowing us to tailor the product to their requirements. Whether it's a trial order or a large quantity, we can accommodate various customization requests.

Supply Chain: These chains have no rotating parts, therefore suffer less from the abrasion caused by sand/dirt, that can come into the mill with the cane. All parts and heat-treated and “T” pins ensure positive locking action in the sidebars.

X678 Chain Drawings:

X678 Chain Specification Parameters

| Chain No | Average Pitch | E(mm) | sidobar | Pin | B(mm) | C(mm) | Min.Ult. Strength Q(KN) | ||

| T(mm) | H(mm) | D(mm) | A(mm) | ||||||

| 468HT | 102.39 | 41.28 | 11.43 | 47.75 | 19.05 | 84.07 | 29.51 | 22.23 | 311.5 |

| 678HT | 153.19 | 33.32 | 18.29 | 50.80 | 22.23 | 76.96 | 21.34 | 25.40 | 378.3 |

| 698HT | 153.19 | 39.67 | 1506 | 68.33 | 28.58 | 95.25 | 26.19 | 31.75 | 602.9 |

| 998HT | 229.39 | 39.67 | 8.26 | 6401 | 28.58 | 98.43 | 25.40 | 28.58 | 602.9 |

| X348 | 76.99 | 19.05 | 10.41 | 26.92 | 12.70 | 44.45 | 13.21 | 14.27 | 106.8 |

| X458 | 102.39 | 25.91 | 12.19 | 36.58 | 15.88 | 55.58 | 16.76 | 17.48 | 213.6 |

| X678 | 153.19 | 33.32 | 18.29 | 50.80 | 22.23 | 76.96 | 21.34 | 25.40 | 378.3 |

The applications of x678 chain

X678 Chain is widely used in overhead conveyor systems, particularly in automotive assembly lines and painting workshops. Its drop-forged structure ensures high load-bearing capacity, while the rivetless design simplifies maintenance and reduces downtime.

In material handling for heavy industries, X678 Chain supports scraper conveyors and cement production lines. Its oil-resistant and heat-resistant properties enable reliable operation in harsh environments like mining and power plants.

X678 Chain serves as a core component in enclosed track conveyors, facilitating smooth movement of trolleys in garment manufacturing and building material distribution. Its 153.2mm pitch and 51.6mm sidebar width enhance stability during high-speed operations.

Customized X678 Chain variants with attachments are tailored for agricultural machinery and snow removal equipment, ensuring compatibility with diverse conveyor systems. The chain’s 320kN tensile strength guarantees durability under extreme loads.

● Mining Industry

In the mining industry, forged chains are widely used in the transportation and processing of ore and the transmission system of mining machinery. Ore is often heavy and irregular in shape, and forged chains can withstand huge loads and work stably to ensure the smooth transportation of ore.

● Cement Industry

In cement production, forged chains are often used to transport raw materials (such as limestone, clay) and finished cement. Since cement production requires handling large amounts of heavy materials and the working environment is often dusty and hot, forged chains are an ideal choice due to their high strength and wear resistance.

● Steel Mill Industry

Forged chains are widely used in steel smelting, furnace material transportation and steel production lines. Since the working environment of steel mills is extremely harsh, with high temperature and heavy load conditions, the high temperature resistance and load-bearing capacity of forged chains enable them to operate stably under these conditions.

Workshops

We have 400 tons punching machines, 100 tons tensile machine, various welding robots and laser cutting equipment, mesh belt furnace, spectrometer, and over 300 sets advanced production and testing equipment.

Automation Group

Punching Group

Heat Treatment Workshop

Welding Workshop

Assembly Group

Laser Cutting Workshop

Quality Testing Center

Stocking Warehouse

Equipment

CNC Milling Machine

Cutting Machine

Heat Treatment with Automatic Mesh Belt Conveyor Furnace

Induction Hardened Machine

Welding Robot

Laser Cutting Equipment

Vacuum Furnace

Multipurpose Furnace

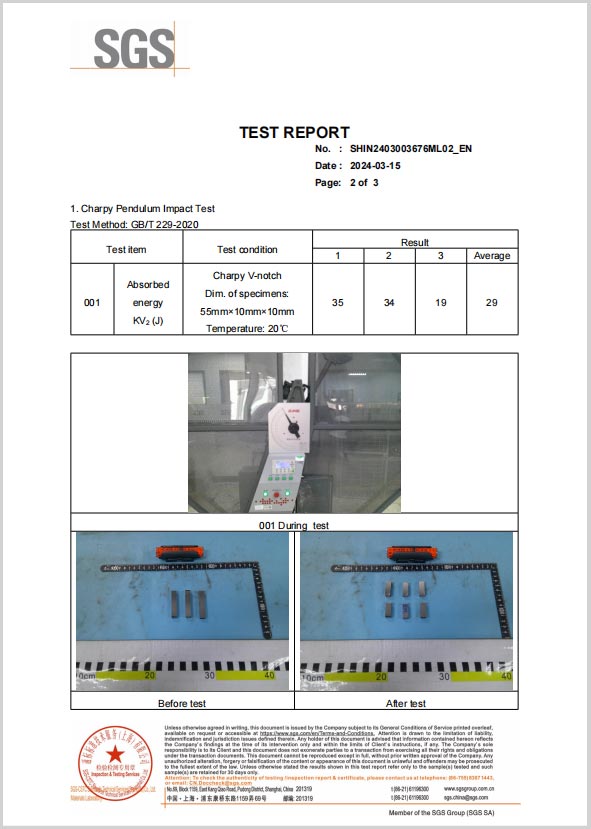

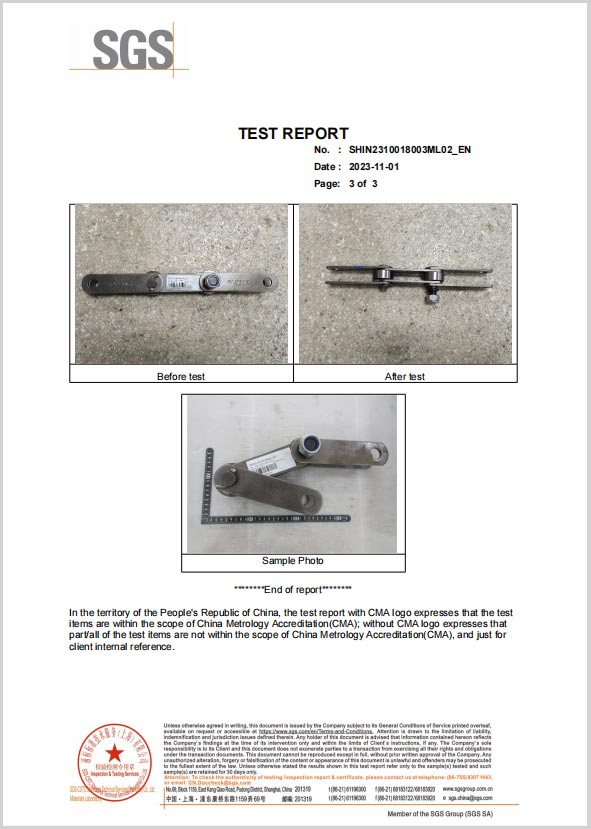

Quality Testing

Impact Testing Machine

Spectrograph

Vickers Hardness Tester

Metallographic Sample Cutting Machine

Pretension Machines

Electronic Rockwell Hardness Tester & Tensile Strength Testing Machine

Precision Length Measuring Instrument

Office

Why Choose JINQIU?

● Over 36 Years' History in Designing and Manufacturing Industrial Chains

With operations in more than 50 countries, we deliver high-quality industrial chains tailored to your needs.

We occupy more than 60,000 square meters, with 8 specialized production workshops, over 300 employees and including 50 in engineering and product developing. We have an annual production capacity of more than 10000 tons, and over 300 sets advanced production equipment and testing equipment.

● Innovative R&D Team Provides Customized Chain Solutions

We provide comprehensive technical support and our dedicated R&D team works closely with customers to design chains that meet unique requirements.

● Flexible Customization & Trial Orders to Meet Your Needs

At Jinqiu Chain, we support full customization and small-batch trial orders, ensuring solutions tailored to your specific applications.

X678 Chain SGS Certificate

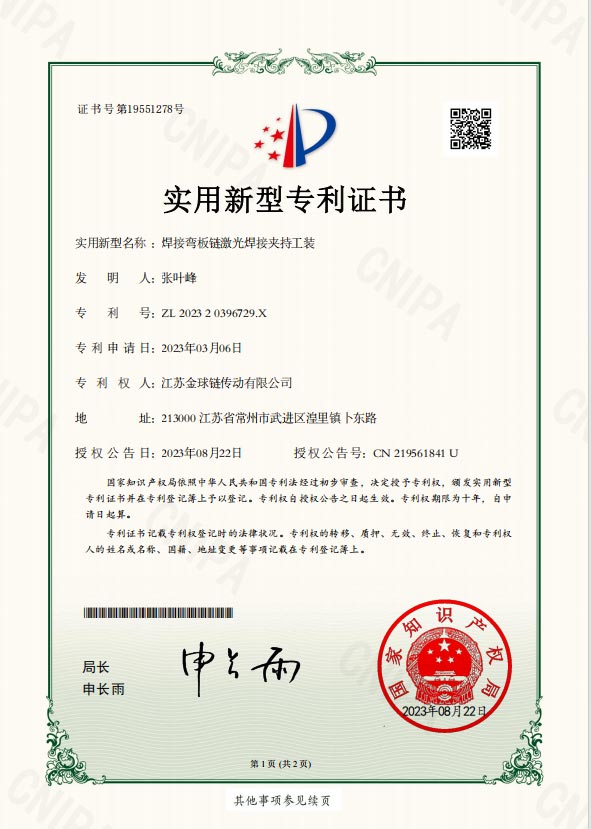

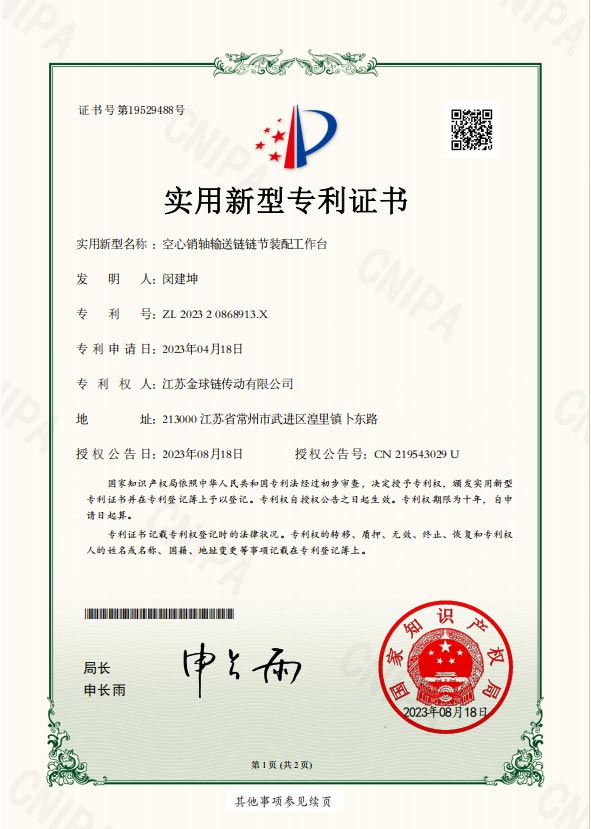

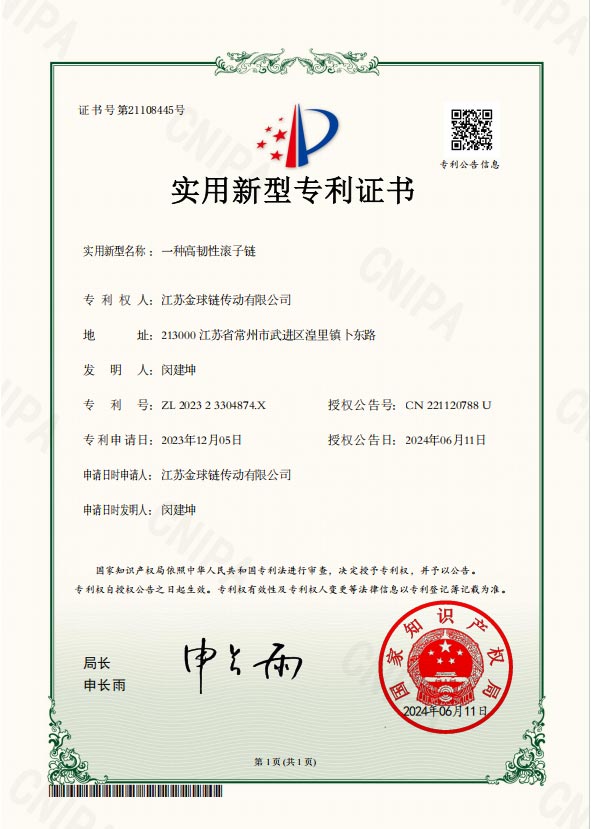

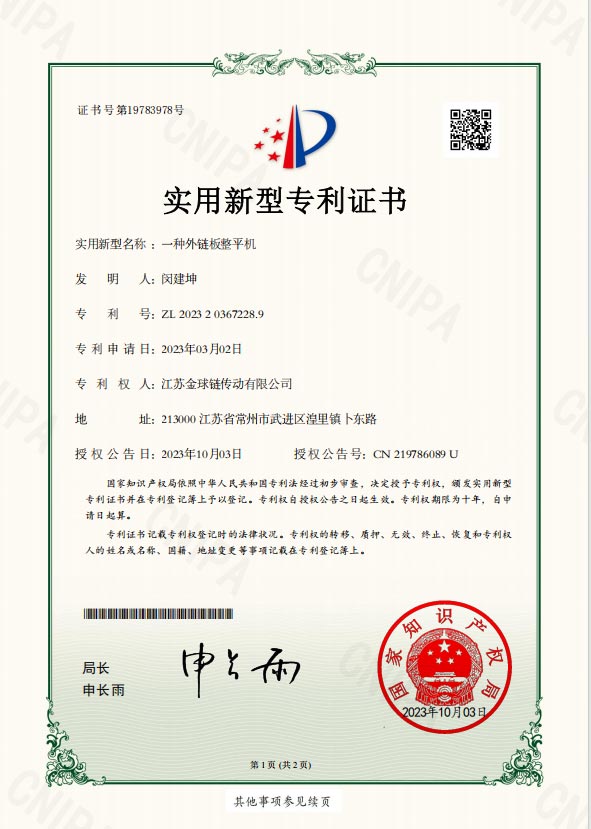

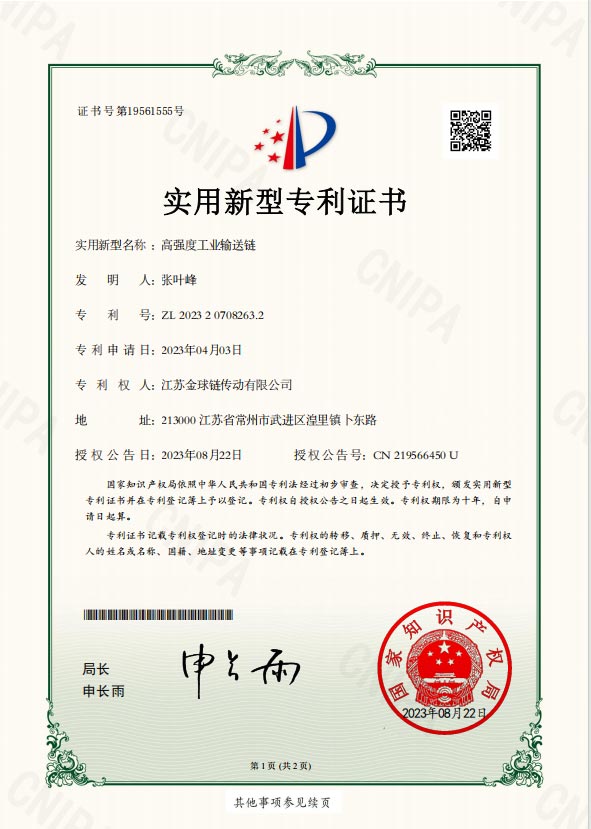

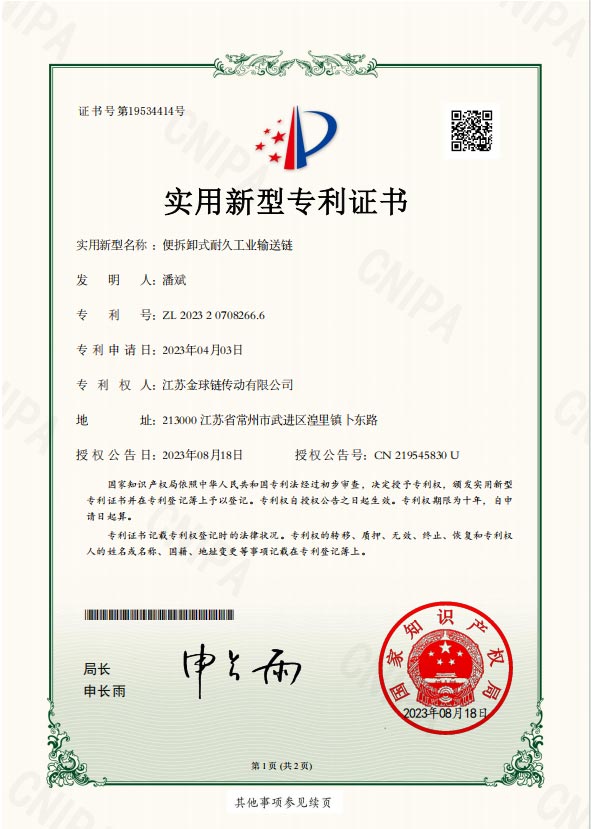

X678 Chain Patent Certificate

After-sales Service

● Professional Technical Guidance

If you have any product questions about chain model selection, production quality, detailed data, troubleshooting, repair and maintenance, you can contact us at any time. We will arrange professional technicians to solve the problem and respond to your needs quickly.

● Free Sample Trial

If you have any doubts about our products, we can provide sample trial services to help you verify the product's suitability and performance before formal purchase.

● Order Tracking & Logistics Support

We provide order progress tracking service for each customer, ensuring that you know the production and delivery status of the product in real time. We provide flexible logistics options and can provide global delivery services according to your location.

● Product Installation Guide

Provide professional installation advice and technical support. You can contact the technical team by phone or online to ensure the smooth installation and commissioning of the chain on the equipment.

● Quality Assurance & After-sales Maintenance

We provide quality assurance for every chain product. If quality problems occur during use (such as chain breakage, wear, etc.), we provide repair or replacement services and ensure that you can resume normal operation in the shortest possible time.

● User Feedback & Improvements

We value every customer's feedback, regularly collect and analyze user opinions, and continuously improve our products and services. If customers have any new needs or suggestions, we will respond and adjust the plan in a timely manner.

Customer Testimonials

| Buyers from Canada: The product quality is very good and meets my expectations. Currently, I have not encountered any problems while using it, and the merchant is very professional. |

| Buyers from USA: Chain quality is amazing and delivery is fast, I like it, look forward to our continued relationship. |

| Buyers from India: Thanks, I think I have a trustworthy partner. You know our needs and try to keep our best interests in mind. Looking forward to our continued relationship. |