A conveyor chain is a critical component in material handling systems, designed to transport goods efficiently across industrial environments. Unlike traditional conveyor belts, which rely on continuous fabric surfaces, conveyor chains utilize interconnected links with specialized components to achieve precise, high-load transportation. This article explores the structure, applications, and technological advancements of conveyor chains, emphasizing their role in modern manufacturing and logistics.

Structure and Components

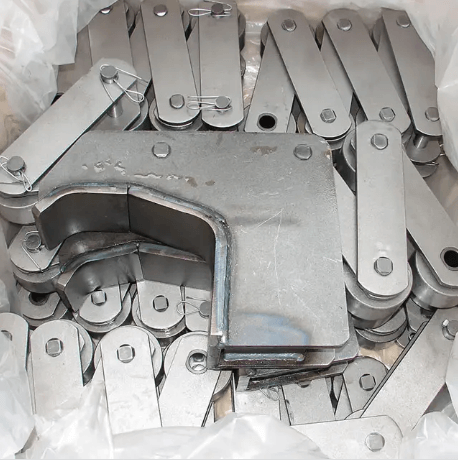

A typical conveyor chain consists of three primary elements: pins, bushings, and rollers. The pins and bushings form the hinge joints between links, allowing smooth articulation under load. Rollers, mounted on the bushings, reduce friction by engaging with guide rails or sprockets. This design enables conveyor chains to withstand heavy weights and resist wear, making them suitable for demanding applications.

Conveyor chains are classified into two main categories: standard roller chains and specialized chains. Standard roller chains, such as the C208A or C212A series, feature uniform link dimensions and are used in general-purpose conveyors. Specialized chains, including accumulation chains and double-plus (speed-up) chains, incorporate additional attachments or modified geometries to optimize specific functions. For example, accumulation chains allow products to pause temporarily without disrupting the entire system, while speed-up chains enable faster transport of workpieces in assembly lines.

Applications Across Industries

Conveyor chains are indispensable in sectors requiring reliable, high-capacity material movement. In automotive manufacturing, they transport car bodies through welding, painting, and assembly stations. The food and beverage industry relies on stainless-steel conveyor chains to move packaged goods while adhering to hygiene standards. In mining and cement production, heavy-duty scraper conveyor chains handle bulk materials like coal, ore, and cement clinker.

Tube chain conveyors, a variant of conveyor chain systems, excel in transporting fine powders and granules. These closed-loop systems use plate-type chains to push materials through horizontal, vertical, or inclined tubes, minimizing dust emissions and product degradation. Applications include conveying titanium dioxide pigment in chemical plants and flour in food processing facilities.

Technological Advancements

Modern conveyor chains integrate innovations to enhance durability and efficiency. Self-lubricating bushings reduce maintenance by retaining grease within the hinge joints, while hardened sprockets extend chain life by minimizing wear. In tube chain conveyors, computer-aided design ensures optimal static friction and pull-up forces, reducing noise and energy consumption.

Another breakthrough is the dual-drive system, which improves load capacity and reliability. For instance, a coal-fired boiler system retrofitted with a redesigned conveyor chain loop achieved simultaneous coal loading, vertical upgrading, and automatic blending, streamlining operations and boosting productivity.

Maintenance and Challenges

Despite their robustness, conveyor chains require regular maintenance. Common issues include chain elongation due to wear, misalignment causing uneven load distribution, and contamination from debris or corrosive substances. To mitigate these risks, operators must monitor chain tension, lubricate joints with appropriate greases, and replace worn components promptly.

In tube chain conveyors, bearing sealing is critical to prevent lubricant leakage and dust ingress. Non-contact seals, such as 2RS-type bearings, are preferred for high-speed applications, as they minimize friction and heat generation.

Conclusion

The conveyor chain remains a cornerstone of industrial automation, offering unmatched versatility in material handling. Its ability to transport heavy loads, navigate complex layouts, and integrate with specialized attachments makes it indispensable in diverse sectors, from automotive assembly to bulk material processing. As industries demand greater efficiency and sustainability, advancements in chain design, such as self-lubrication and dual-drive systems, will further enhance performance. By prioritizing proper maintenance and leveraging technological innovations, manufacturers can maximize the lifespan and reliability of their conveyor chains, ensuring seamless operations in an increasingly competitive landscape. The conveyor chain is not merely a component—it is a catalyst for productivity, embodying the precision and resilience required in modern industrial ecosystems.