| Availability: | |

|---|---|

Features of China conveyor chain sugar chain:

Exceptional Durability: The conveyor chain sugar chain is made from high - grade materials like stainless steel and alloy steel. This ensures remarkable durability, withstanding the harsh conditions in sugar mills, such as the abrasive nature of sugarcane and beet during transportation.

Corrosion Resistance: Given the sugary and often moist environment in sugar production, this conveyor chain features excellent corrosion resistance. It can resist the corrosive effects of sugar juice, preventing premature wear and ensuring long - term reliable operation.

High Load - Bearing Capacity: Engineered to handle heavy loads, the China conveyor chain sugar chain can transport large quantities of sugarcane or sugar products. It maintains stable performance even when carrying substantial weights, facilitating efficient production flow.

Customizable Design: It offers a customizable design. Different pitch sizes, attachments, and configurations can be tailored to the specific equipment layout and production requirements of various sugar mills, enhancing its adaptability.

Low Maintenance: With a well - thought - out design, the conveyor chain sugar chain requires minimal maintenance. This allows sugar mills to operate smoothly, especially during peak processing seasons, without frequent disruptions for upkeep.

Drawings of conveyor China chain sugar chain:

Specification Parameters

| Chain No | Pilch P | E(mm) min | Sidebar | Pin | Bush | Roller | Avora go Ulimato Strength Q(KN) | ||

| T(mm) | H(mm) | D(mm) | A(mm) | R(mm) | F(mm) | ||||

| 2397 M14 | 1524 | 55.5 | 10 | 63.5 | 22.2 | 116.00 | 31.75 | 44.5 | 380 |

| 2358 M14 | 228.6 | 49.23 | 12.70 | 63.50 | 22.23 | 154.20 | 32.20 | 44.45 | 472 |

| 1707 M14 | 304.8 | 76.20 | 12.70 | 63.50 | 25.40 | 154.76 | 38.10 | 57.15 | 617 |

| 2614 M14 | 304.8 | 69.85 | 15.88 | 88.90 | 31.75 | 161.90 | 44.30 | 63.50 | 900 |

| 2630 M14 | 304.8 | 69.85 | 1588 | 88.90 | 34.90 | 162.70 | 47.75 | 63.50 | 980 |

| 12220M14 | 304.8 | 70.64 | 15.88 | 101.60 | 38.10 | 161.44 | 53.98 | 79.38 | 1125 |

| 1223 M14 | 304.8 | 70.61 | 15.88 | 101.60 | 38.10 | 195.58 | 53.98 | 88.90 | 1350 |

| 2648 M14 | 304.8 | 92.20 | 19.05 | 101.60 | 41.40 | 196.85 | 82.55 | 101.60 | 1575 |

● Sugar Industry

In sugar industry, sugar mill chain has to be abrasion and corrosion resistant since it is inevitably exposed to strong impacts and corrosive environments. We offer a complete range chains in sugar mills from cane carrier, Inter-carrier and bagasse conveyor. We have rich design experience and manufacturing technology, and can provide system solutions for you.

Why Choose Our Sugar Chain?

We are not just chain manufacturers; we are industry partners dedicated to providing comprehensive solutions tailored to your applications. Our expertise in the sugar industry enables us to deliver:

• Durable and Reliable Chains

Engineered with high-grade materials and advanced coatings to withstand the corrosive and abrasive conditions in sugar production.

• Expert Technical Support

Our experienced engineers analyze your challenges and offer customized recommendations to optimize performance and extend chain lifespan.

• Preventive Maintenance Guidance

We provide insights into best practices for conveyor maintenance, ensuring smooth operations and reducing downtime.

The Benefits of Our Chains for the Sugar Industry

• Reduced Downtime

Minimized wear and tear ensures consistent production without unexpected halts.

• Improved Efficiency

Smooth, reliable chain performance enhances conveyor operation, increasing throughput.

• Extended Chain Lifespan

Corrosion-resistant designs and proper maintenance practices significantly reduce replacement frequency.

• Cost Savings

By preventing premature wear and reducing maintenance needs, our solutions lower long-term operational costs.

Workshops

We have 400 tons punching machines, 100 tons tensile machine, various welding robots and laser cutting equipment, mesh belt furnace, spectrometer, and over 300 sets advanced production and testing equipment.

Automation Group

Punching Group

Heat Treatment Workshop

Welding Workshop

Assembly Group

Laser Cutting Workshop

Quality Testing Center

Stocking Warehouse

Equipment

CNC Milling Machine

Cutting Machine

Heat Treatment with Automatic Mesh Belt Conveyor Furnace

Induction Hardened Machine

Welding Robot

Laser Cutting Equipment

Vacuum Furnace

Multipurpose Furnace

Quality Testing

Impact Testing Machine

Spectrograph

Vickers Hardness Tester

Metallographic Sample Cutting Machine

Pretension Machines

Electronic Rockwell Hardness Tester & Tensile Strength Testing Machine

Precision Length Measuring Instrument

Office

Why Choose JINQIU?

● Over 36 Years' History in Designing and Manufacturing Industrial Chains

With operations in more than 50 countries, we deliver high-quality industrial chains tailored to your needs.

We occupy more than 60,000 square meters, with 8 specialized production workshops, over 300 employees and including 50 in engineering and product developing. We have an annual production capacity of more than 10000 tons, and over 300 sets advanced production equipment and testing equipment.

● Innovative R&D Team Provides Customized Chain Solutions

We provide comprehensive technical support and our dedicated R&D team works closely with customers to design chains that meet unique requirements.

● Flexible Customization & Trial Orders to Meet Your Needs

At Jinqiu Chain, we support full customization and small-batch trial orders, ensuring solutions tailored to your specific applications.

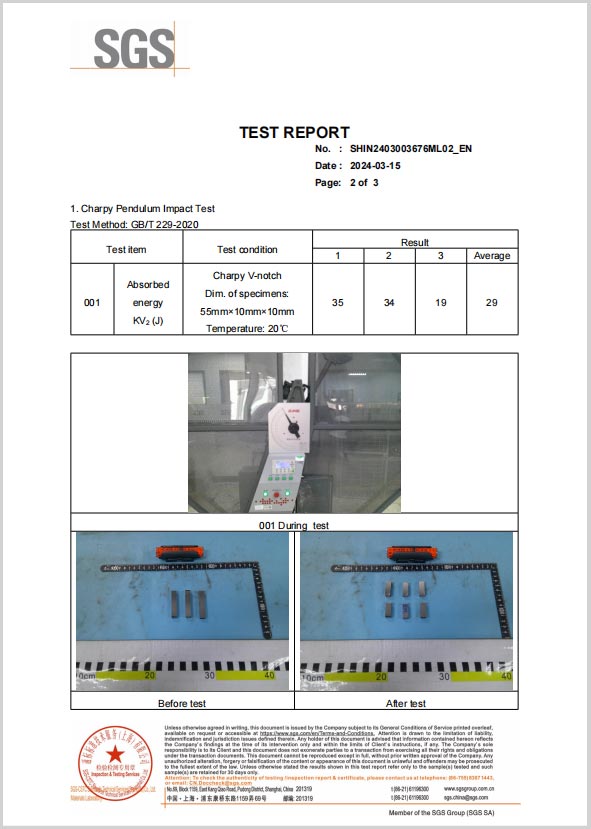

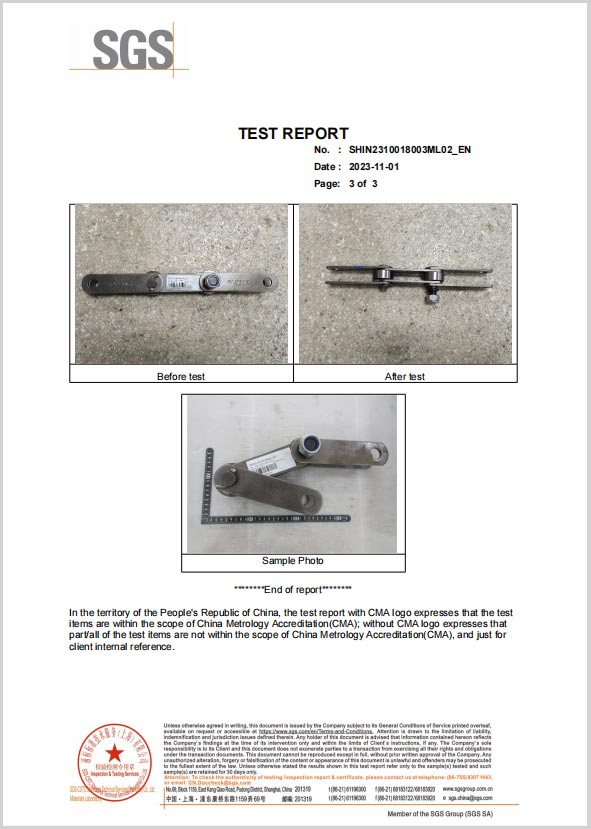

SGS Certificate

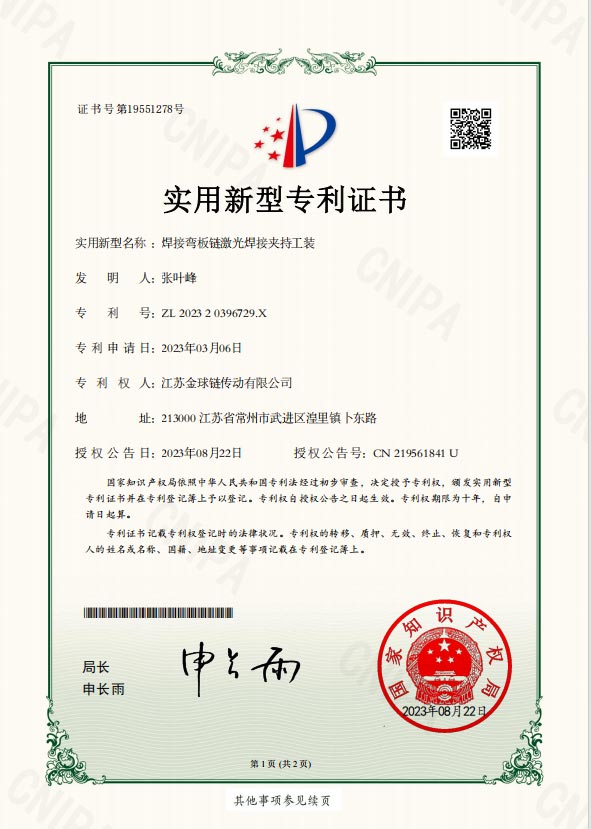

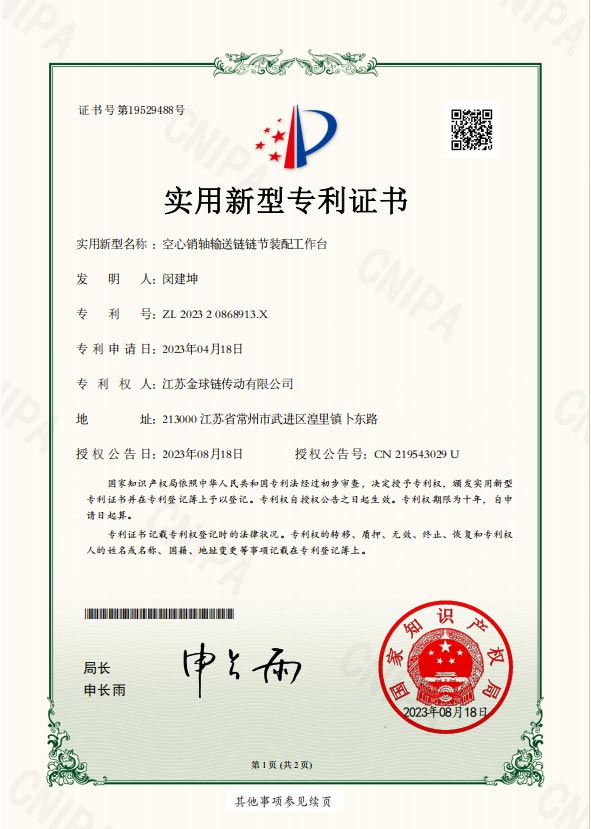

Patent Certificate

After-sales Service

● Professional Technical Guidance

If you have any product questions about chain model selection, production quality, detailed data, troubleshooting, repair and maintenance, you can contact us at any time. We will arrange professional technicians to solve the problem and respond to your needs quickly.

● Free Sample Trial

If you have any doubts about our products, we can provide sample trial services to help you verify the product's suitability and performance before formal purchase.

● Order Tracking & Logistics Support

We provide order progress tracking service for each customer, ensuring that you know the production and delivery status of the product in real time. We provide flexible logistics options and can provide global delivery services according to your location.

● Product Installation Guide

Provide professional installation advice and technical support. You can contact the technical team by phone or online to ensure the smooth installation and commissioning of the chain on the equipment.

● Quality Assurance & After-sales Maintenance

We provide quality assurance for every chain product. If quality problems occur during use (such as chain breakage, wear, etc.), we provide repair or replacement services and ensure that you can resume normal operation in the shortest possible time.

● User Feedback & Improvements

We value every customer's feedback, regularly collect and analyze user opinions, and continuously improve our products and services. If customers have any new needs or suggestions, we will respond and adjust the plan in a timely manner.

Customer Testimonials

| Buyers from Canada: The product quality is very good and meets my expectations. Currently, I have not encountered any problems while using it, and the merchant is very professional. |

| Buyers from USA: Chain quality is amazing and delivery is fast, I like it, look forward to our continued relationship. |

| Buyers from India: Thanks, I think I have a trustworthy partner. You know our needs and try to keep our best interests in mind. Looking forward to our continued relationship. |