A welded chain has strong welded links that join each part. This makes it one of the most reliable chains you can get. You can trust a welded chain because it is strong and lasts a long time. These things are important for tough jobs. Many industries use welded chains. Some examples are automotive, food processing, mining, and construction. The global market for welded steel conveyor chains is growing fast. It may reach almost 1.9 billion dollars by 2033. Jinqiu Chain is a trusted maker. They offer high-quality, customizable chain solutions. They have many years of experience.

Welded chains are very strong and dependable. They work well for tough jobs in many industries. These chains last a long time and do not need much care. This helps you save money as time goes on. Welded chains are safer than other kinds. They lower the chance of breaking while you use them. Picking the right grade and type of welded chain is very important. It helps keep your work safe and efficient. Jinqiu Chain makes welded chains you can customize. These chains fit special needs for different uses.

You can find a welded chain in many places where strength is needed. This chain has links joined together by welding. Each link connects tightly to the next one. The welded spots make the chain strong and dependable. People use welded chains for lifting, pulling, or holding heavy things. These welded steel chains work well in hard conditions. They do not wear out fast and last longer than many other chains.

Tip: Welded chains are liked because they stay together well. The welded parts keep the chain strong under pressure.

Here is a table that shows how welded chains are different from other chains:

Chain Type | Strength | Durability | Applications |

|---|---|---|---|

Forged Link Chains | More higher | High resistance to wear | Heavy lifting, mining, marine, etc. |

Welded Steel Chains | High | Easy to wear at the weld points | Moderate-duty applications, general use |

Jinqiu Chain uses special welding methods to make sure every welded chain is safe and strong. You get a product that you can trust.

When you pick welded chains, you get many good things:

Very strong and tough for big jobs

Saves money because they last and need less fixing

Safer design that helps stop chain breaks

You can trust welded chain products from Jinqiu Chain. The company cares about quality and new ideas. Their welded chains go through careful checks to make sure they work well.

You might wonder how people make welded chains. The process has many steps to make sure each chain is strong and the same. Here is a simple list:

Phase | Description |

|---|---|

1 | Raw Material Preparation: Workers get steel wire rods ready by uncoiling and putting oil on them. They pull the rods through a die to make them thinner and stronger. |

2 | Forming the Links: Machines bend the wire into a 'C' shape, cut it, and shape each link to look the same. |

3 | Welding and Heat Treatment: Workers weld the links together to make a solid chain. They use heat to make the chain even stronger. |

4 | Final Processing: Workers check, test, and finish the chain to make sure it is good and strong. |

Jinqiu Chain checks quality at every step. You get many inspections, like checking welds, size, and heat treatment. The company tests each welded chain for hardness, how much it can hold, and how much it stretches. You get a chain that meets world standards.

Note: Quality checks are very important in making welded chains. Jinqiu Chain watches and tests everything to give you the best products.

You will see that welded chains are made from different kinds of steel. Makers use carbonaceous, alloyed, and high-alloyed steel for different jobs. Steel is used most because it is strong and lasts long.

Steel (including alloyed, high-alloyed, and carbonaceous) is often used to make welded chains.

The kind of steel changes how strong the chain is and how much it can hold.

Steel with more carbon makes the chain stronger and harder to wear out.

Heat treatment makes the steel even tougher for big jobs.

Here is a table that shows how the material changes the strength and life of welded chains:

Evidence Description | Impact on Strength and Durability |

|---|---|

Higher carbon-content steel is often used, resulting in chains with high tensile strength and resistance to abrasive action. | This kind of steel helps the chain last longer and not wear out fast. |

The quality of the steel, whether high-grade or low-grade, determines the chain's strength and its maximum working load capacity. | Better steel makes stronger chains that can hold more weight. |

Heat treatment of basic steel further enhances its strength, making it suitable for heavy-duty applications. | Heat treatment makes the chain stronger so it works better in hard jobs. |

The ultimate breaking strength of a chain is determined by its grade. | Higher grades mean the chain is stronger and better for tough work. |

Jinqiu Chain picks the best materials for every welded chain. You get a chain that fits your needs and can handle hard work.

When you compare a welded chain to a twisted chain, you notice some big differences. A welded chain has links that are joined by welding. This makes each link strong and keeps the chain from coming apart. A twisted chain has links that are twisted together, not welded. This design can make the chain less strong. You may find that a twisted chain works for light tasks, but it does not handle heavy loads as well as a welded chain. If you need a chain for lifting, pulling, or securing heavy items, you should choose a welded chain for better safety and strength.

Feature | Welded Chain | Twisted Chain |

|---|---|---|

Link Connection | Welded | Twisted |

Strength | High | Lower |

Best Use | Heavy-duty tasks | Light-duty tasks |

Tip: Use a welded chain when you need extra strength and reliability.

You might also see chains with soldered links. Soldered chains use melted metal to join the links, but this bond is not as strong as welding. A welded chain has a seamless connection at each link. This makes it much harder for the chain to break or fail. Soldered chains can work for crafts or decorations, but you should pick a welded chain for jobs that need real strength. When you want a chain that will not let you down, welded chains are the better choice.

Welded chains offer several key benefits that set them apart from other types of chain:

Exceptional strength lets you use welded chains for heavy loads.

Durability means you can trust these chains in tough indoor or outdoor settings.

Reliability comes from seamless welding, which lowers the risk of failure.

You can count on a welded chain to perform well in many situations. Whether you work in construction, farming, or shipping, welded chains give you peace of mind. They last longer and keep your work safe.

You will find many types of welded chain in the market. Each type has a special use. Some of the most common welded chains include:

Proof coil chain: You can use this for general purposes, like securing gates or fences.

High-test chain: This chain works well for towing, anchoring, and securing heavy equipment.

Alloy chain: You should use this for lifting and overhead tasks because it is very strong.

Welded steel chains also come in many forms for industry. You might see engineering drive chain, conveyor chain, welded steel mill and drag chain, rooftop chain, drop forged rivetless chain, cast chain, and 81X heavy chain. These welded steel chains are popular in lumber, agriculture, and pulp industries. Some chains, like the 400 Series Pintle Chain, handle medium loads, while the 700 Series Pintle Chain resists corrosion in coastal areas.

Tip: Always choose the right welded chain for your job to keep your work safe and efficient.

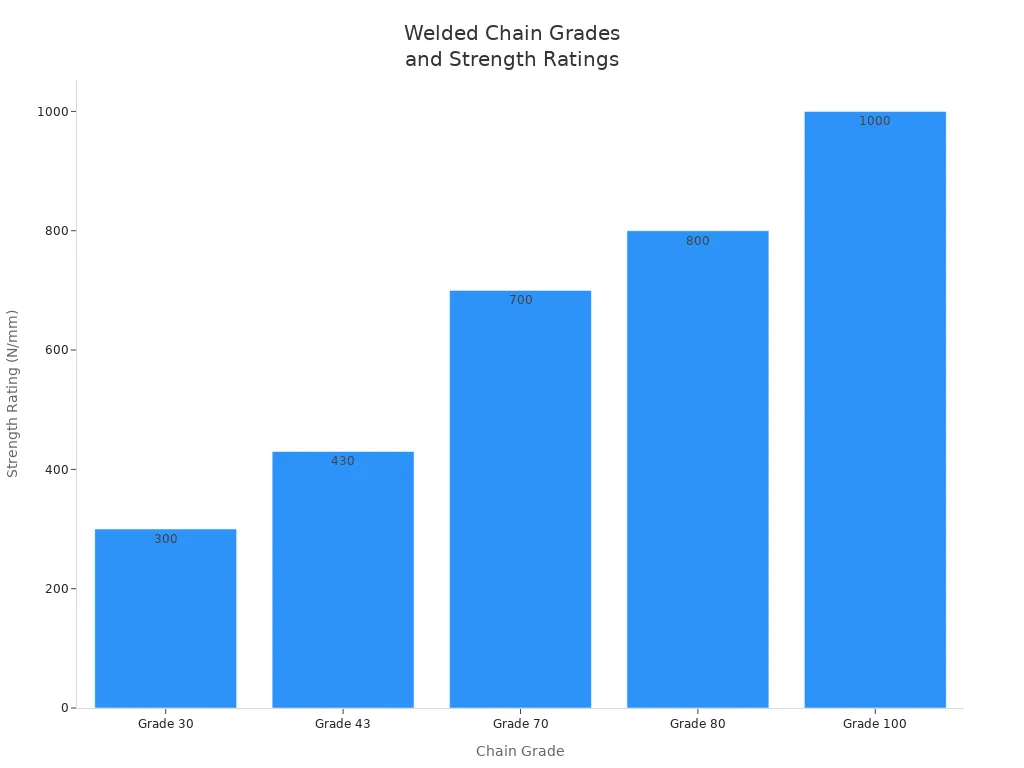

Welded chains come in different grades. Each grade shows how much weight the chain can handle. You can check the table below to compare the most common grades:

Chain Grade | Description | Material | Diameter Range | Strength Rating |

|---|---|---|---|---|

Grade 30 | General-purpose, not for overhead lifting | Low carbon steel | 1/8” to 3/4” | 300 N/mm |

Grade 43 | High strength, not for overhead lifting | Carbon steel | 1/4” to 3/4” | 430 N/mm |

Grade 70 | Load binding, towing, not for overhead lifting | Heat treated carbon steel | 1/4” to 1/2” | 700 N/mm |

Grade 80 | Overhead lifting | Heat treated alloy steel | 7/32” to 1-1/4” | 800 N/mm |

Grade 100 | Strongest, for overhead lifting | Heat treated alloy steel | 9/32” to 7/8” | 1000 N/mm |

You will notice that welded steel chain grades 80 and 100 are best for heavy lifting. Lower grades, like 30 and 43, work well for lighter jobs. The strength of welded chains comes from their tightly joined links. This design spreads weight evenly and reduces weak spots.

When you pick a welded chain, you need to think about your task. Not every welded chain fits every job. Proof coil and high-test chains are great for towing, anchoring, and securing cargo. Alloy welded chains are best for lifting heavy loads. Always check the grade and material before you use a welded steel chain. This helps you stay safe and get the best results.

Note: Using the right welded chain for your job keeps your equipment and team safe. Always follow safety rules and check the chain’s grade before use.

Welded chains are important in many industries. You see them in construction, farming, factories, shipping, security, and even in forests, mines, and on boats. Each industry needs welded steel chains because they are strong and dependable. Jinqiu Chain makes special chains for different jobs. This helps you get the right chain every time.

Construction work is hard and needs tough tools. Welded chains help lift, pull, and hold heavy things. You use them to raise beams, move blocks, and keep scaffolding safe. These chains help cranes and winches work better. Their strong links do not break easily, even when stressed. Welded chains in construction meet strict safety rules. Jinqiu Chain can change the size, grade, or finish to fit your project.

Farm machines get dirty and work a lot. Welded chains are good for these tough jobs. You use them in tractors, harvesters, and balers. They help move hay, feed, and run conveyors. Welded chains can handle shocks and big temperature changes. They work in cold mornings and hot afternoons. They also work well in wet fields and muddy barns.

Welded chains keep working in dirt and dust.

They last through heavy use and heat.

These chains handle quick changes from cold to hot.

Welded chains work well in wet places.

Jinqiu Chain can make welded steel chains for your farm tools. This helps your equipment last longer in any weather.

Factories and warehouses use welded chains for many jobs. You use them to move things, lift heavy parts, and run conveyors. Welded chains carry coal, ores, grains, seeds, and cement. They work in mining, farming, food plants, and heavy industry. These chains must meet strict load rules to keep workers safe.

Mining: Welded chains move coal, ores, and minerals.

Farming and food: Chains move grains and seeds safely.

Construction and heavy work: Chains carry rocks and cement.

Material Type | Recommended Use | Load Capacity Standards | |

|---|---|---|---|

30 | Carbon Steel | Not for overhead lifting | OSHA, ASME |

80 | Alloy Steel | Good for overhead lifting | OSHA, ASME |

100 | Alloy Steel | Good for overhead lifting | OSHA, ASME |

Jinqiu Chain makes welded chains that meet these rules. This helps you lift and move things safely.

You need to keep cargo safe when moving it. Welded chains give you the strength you need for big jobs. You use them to tie down loads on trucks, trailers, and ships. These chains also help tie up boats and anchor gear in marine jobs. Their welded design stops stretching and breaking, even with heavy loads.

Keep loads safe during transport in construction.

Tie up boats and anchor gear in marine jobs.

Secure trailers and gear when towing or mooring.

Welded transport chains use strong steel and tough welds. This makes them great for holding cargo. Jinqiu Chain can make welded chains for your transport needs. This keeps your cargo safe on land or water.

You want to keep your things safe. Welded chains make a strong barrier against theft. You use them to lock bikes, boats, gates, and storage units. Thick chain links are hard to cut. Welded links cannot be pulled apart like loose ones. Case-hardened and through-hardened links stop saws and bolt cutters.

Factor | Description |

|---|---|

Thickness of the chain link | Thicker metal is harder to cut, so it is safer. |

Welded links | Welded links cannot be pulled apart, making the chain safer. |

Case hardened links | The surface is hard, so it is tough to saw through. |

Through hardened links | These links are tough against bolt cutters, so they are safer. |

Applications | Used to lock up bikes, boats, and property, making a strong barrier. |

Jinqiu Chain can give you welded steel chains with the right thickness and hardness for your safety needs.

Welded chains help with the hardest jobs in forests, mines, and on boats. You use them to move logs, run big machines, and tow or anchor boats. These chains must not rust, must hold heavy loads, and must work in tough places.

Industry | Application Description |

|---|---|

Forestry | Welded steel chains move heavy logs and run machines in the forest. |

Mining | Strong, rust-proof chains work in tough mines, making work safer. |

Marine | Chains tow and anchor boats, giving strength and safety in rough water and salty air. |

Jinqiu Chain can make welded chains for these hard jobs. They use special coatings and materials to make chains last longer.

Tip: Welded chains are used in many industries. You can ask Jinqiu Chain for help picking the best chain for your job.

You can see welded chains are needed for many jobs. Their strength, long life, and many uses make them the best choice for lifting, holding, and moving heavy things in every big industry.

You have seen how a welded chain gives you strength, safety, and long life in many industries. When you pick the right chain type and grade, you keep your work safe and efficient. Jinqiu Chain offers you welded chains that fit your needs. You get quality, custom options, and expert support.

Ready to upgrade your operations? Contact Jinqiu Chain today for the best welded chain solutions!

You get welded chains with links joined by welding. This makes them stronger and less likely to break. Twisted or soldered chains do not have this strong bond. Welded chains work better for heavy-duty jobs.

Yes, you can use welded chains outdoors. They resist rust and weather when made from the right materials or have special coatings. You should pick the right type for your outdoor job.

You should check the chain’s grade, size, and material. Think about how much weight you need to lift or secure. Ask a professional if you are not sure which chain fits your needs.

Yes, welded chains are safe for lifting when you use the correct grade and size. Always follow safety rules and never use a chain for more weight than its rated capacity.

Yes, you can order custom welded chains. You can choose the length, thickness, and coating. This helps you get the best chain for your project.