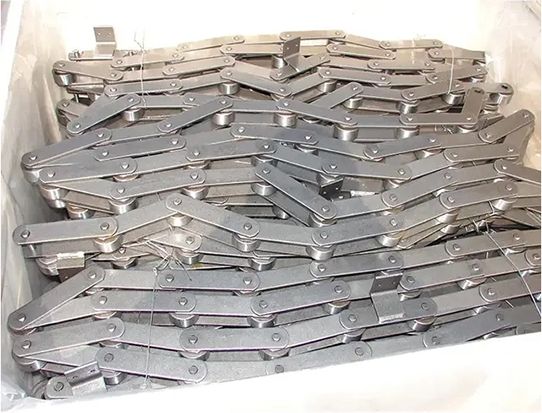

Conveyor systems are essential components in industries such as manufacturing, logistics, and mining, ensuring the efficient and seamless movement of goods and materials. Among the various elements of a conveyor system, conveyor chains play a pivotal role. However, over time, these chains can wear out, stretch, or become misaligned, leading to operational inefficiencies and potential breakdowns. Regularly adjusting conveyor chains is vital to maintaining optimal performance and extending their lifespan. This article will guide you through the process of adjusting conveyor chains effectively.

1.Understanding the Importance of Proper Conveyor Chain Adjustment

Conveyor chain adjustment is critical for several reasons. Firstly, it ensures the smooth operation of the conveyor system, preventing jams or stoppages that can disrupt production. Secondly, it reduces wear and tear on the chain and other components, such as sprockets and bearings, thereby lowering maintenance costs and minimizing downtime. Properly adjusted conveyor chains also enhance safety by reducing the risk of accidents caused by malfunctioning equipment.

2.Conducting a Preliminary Inspection

Before adjusting conveyor chains, it's essential to conduct a thorough inspection. Begin by visually examining the chain for signs of wear, such as elongation, corrosion, or broken links. Check the sprockets for wear and ensure they are aligned correctly. Additionally, inspect the conveyor's structure for any damage or misalignment that could affect the chain's operation. This initial assessment provides a baseline for determining the necessary adjustments.

3.Measuring Chain Tension

One of the primary aspects of conveyor chain adjustment is ensuring the correct tension. A chain that is too loose can cause slippage, while a chain that is too tight can lead to excessive wear and premature failure. To measure chain tension, use a chain tension gauge or follow a manual method involving a straightedge and a ruler. Place the straightedge against the chain and measure the sag between two sprockets. The optimal sag varies depending on the conveyor's specifications, so refer to the manufacturer's guidelines for precise measurements.

4.Adjusting Chain Tension

Once you've determined the current tension and identified whether it's too loose or too tight, it's time to make adjustments. Typically, conveyor systems have adjustment mechanisms, such as take-up units, that allow you to modify the chain's tension. Loosen the locking nuts on the take-up unit, turn the adjusting screw to increase or decrease tension as needed, and then retighten the nuts to secure the adjustment. It's crucial to make small, incremental adjustments and recheck the tension until it falls within the recommended range.

5.Checking and Aligning Conveyor Chain Sprockets

Misaligned sprockets can cause uneven wear on the conveyor chain and lead to premature failure. Ensure that the sprockets are aligned correctly by checking their positioning and ensuring they are parallel to the conveyor frame. Misalignment can be corrected by adjusting the sprocket position or, if necessary, replacing worn sprockets.

6.Lubricating Conveyor Chains

Proper lubrication is essential for reducing friction and wear on conveyor chains. Regularly apply the recommended lubricant to the chain, following the manufacturer's guidelines for the type and frequency of lubrication. Lubrication not only extends the chain's lifespan but also ensures smooth operation and reduces energy consumption.

7.Testing and Monitoring

After making adjustments, it's crucial to test the conveyor system to ensure the changes have had the desired effect. Run the conveyor at a reduced speed to observe the chain's performance. Check for any unusual noises, vibrations, or misalignments and address them promptly.

Conclusion

Adjusting conveyor chains is a critical maintenance task that ensures the efficient and safe operation of conveyor systems. By following the steps outlined in this article—conducting regular inspections, measuring and adjusting chain tension, ensuring proper alignment, and maintaining adequate lubrication—you can significantly improve the performance and longevity of your conveyor chains. Regular maintenance and adjustment not only prevent breakdowns but also enhance operational efficiency and safety. Remember, conveyor chain adjustment is an ongoing process that requires attention to detail and adherence to best practices to achieve optimal results.