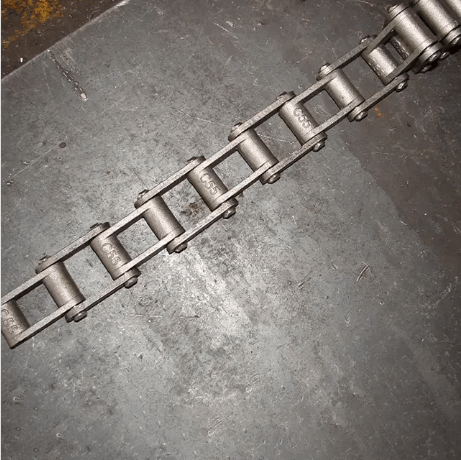

The C55 chain is a specialized cast combination chain widely recognized for its robustness and versatility in industrial applications. From grain handling systems to forest product processing, this chain plays a pivotal role in ensuring smooth and reliable material transfer. To fully understand its capabilities, it’s essential to delve into its precise dimensions, mechanical properties, and design features that define its size and performance.

Core Dimensions of the C55 Chain

The C55 chain is characterized by a 1.631-inch pitch, which refers to the distance between the centers of adjacent pins. This pitch size is critical as it determines the chain’s compatibility with sprockets and its overall load-bearing capacity. The chain’s width varies depending on its construction type:

Riveted construction: The overall width is 1.970 inches, offering a compact profile suitable for tight spaces.

Cottered construction: The width increases slightly to 2.060 inches, providing enhanced stability in heavy-duty applications.

Additional key dimensions include:

Pin diameter: 0.375 inches, ensuring durability under high tensile forces.

Sidebar height: 0.750 inches, contributing to the chain’s structural integrity.

Barrel diameter: 0.720 inches, which affects the chain’s articulation and wear resistance.

Barrel length: 1.250 inches, optimizing the chain’s engagement with sprockets.

These measurements collectively define the C55 chain’s physical footprint, enabling engineers to select it for systems where precise sizing is non-negotiable.

Mechanical Properties and Load Capacity

The C55 chain’s size is inextricably linked to its mechanical performance. With an average ultimate tensile strength of 12,150 pounds, it can withstand extreme forces without failure. However, its maximum recommended working load of 1,400 pounds highlights the importance of operating within safe limits to prevent premature wear or catastrophic failure.

The chain’s design also incorporates a maximum allowable sprocket face width of 0.690 inches, ensuring proper alignment and reducing stress on components. This specification is particularly vital in high-speed applications, where misalignment can lead to rapid degradation.

Applications and Design Adaptability

The C55 chain’s compact yet sturdy size makes it ideal for a range of industries. In grain handling, its resistance to abrasive particles ensures longevity in silos and elevators. For forest product processing, its ability to operate in gritty environments minimizes downtime. The chain’s symmetric links further enhance its versatility, allowing bidirectional movement without compromising performance—a feature critical in conveyor systems requiring reversible operation.

Manufacturers often pair the C55 chain with custom attachments, such as buckets or flights, to tailor it to specific tasks. Its compatibility with standardized sprockets (e.g., 26-tooth sprockets with a pitch diameter of 13.53 inches) simplifies integration into existing systems, reducing upgrade costs.

Construction Variants and Weight Considerations

The C55 chain is available in riveted and cottered constructions, each offering distinct advantages. Riveted chains are preferred for applications requiring frequent disassembly, as they are easier to maintain. Cottered chains, while slightly wider, provide superior stability in static or low-speed, high-load scenarios.

Weight is another critical factor. A 10-foot reel of riveted C55 chain weighs approximately 20.8 pounds, translating to 2.2 pounds per foot. This lightweight design reduces energy consumption in conveyor systems while maintaining the strength needed for heavy loads.

Conclusion

The C55 chain’s size is a harmonious blend of precision dimensions, mechanical resilience, and adaptive design. Its 1.631-inch pitch, coupled with variations in width and construction, ensures it meets the demands of diverse industrial environments. Whether in grain elevators, sugar processing plants, or forest product mills, the C55 chain’s compact yet powerful profile makes it an indispensable component. By understanding its size specifications—from pin diameter to tensile strength—engineers and operators can leverage the C55 chain to optimize efficiency, reduce maintenance costs, and extend equipment lifespan. In the world of industrial conveying, the C55 chain stands as a testament to how thoughtful engineering can transform size into strength.